Hard Drive PCB Repair Case Study: What Happened?

A customer sent us a Western Digital hard drive that was completely dead. No spinning. No detection. Our diagnostics confirmed the printed circuit board (PCB) was shorted due to a power surge. Components like capacitors and diodes were visibly burnt. Without professional PCB repair, data from this drive would have been lost forever.

Can Hard Drive PCB Repair Recover Data?

Yes, but only with expert knowledge and specialist tools. Many customers try DIY fixes or swap PCBs from similar drives, but this causes permanent damage if the ROM chip is not transferred. This chip contains calibration data unique to each drive. In this case, our engineers used PC-3000 tools and soldering stations to remove and reattach the ROM chip to a working donor board. This process, known as ROM transfer, is essential for successful hard drive PCB repair.

How We Repaired the PCB and Recovered the Data

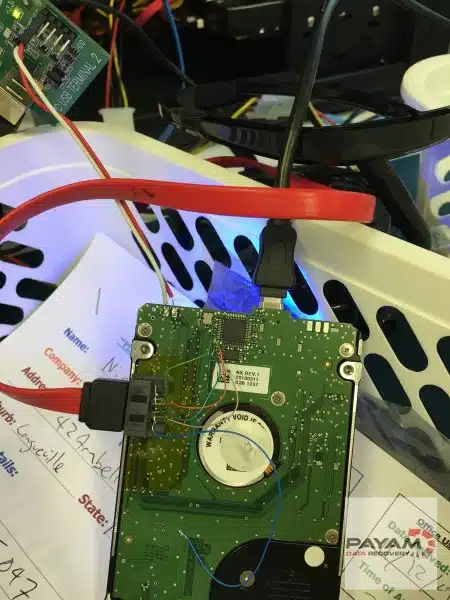

- Assessment: Our lab performed a free 1–2 day assessment using PC-3000 diagnostics to confirm PCB failure and determine the correct donor board.

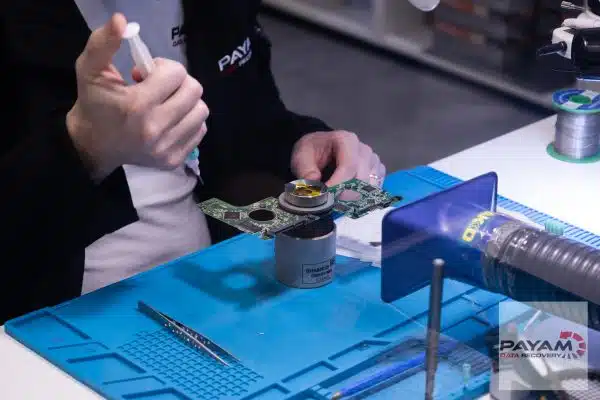

- ROM Chip Transfer: Using heat-controlled soldering, our engineer safely moved the ROM chip from the damaged board to a healthy donor PCB.

- Testing: The repaired drive was reconnected to PC-3000 equipment. The hard drive spun up, calibrated correctly, and gave us full access to the user data.

- Data Cloning: All data was imaged sector-by-sector onto a new drive, ensuring integrity and file completeness.

Professional Tips for PCB Repair

- Don’t try swapping boards blindly: Even if model numbers match, firmware and ROM data must align.

- Control the heat: ROM chips are heat-sensitive. Too much heat destroys them, making recovery impossible.

- Use the right tools: PC-3000, hot air stations, and antistatic environments are essential for safe PCB work.

What Was the Outcome?

The PCB swap was successful. All user data was recovered and delivered to the client on a new external drive. This case reinforces that circuit board repair should never be attempted without proper training and lab-grade tools. Payam Data Recovery handled this case quickly and safely using ISO-certified cleanroom conditions and highly skilled engineers.

Why Trust Payam with Your Hard Drive Repair?

We’re Australia’s oldest data recovery company, operating since 1998. With over 150,000 successful recoveries and six labs across Sydney, Melbourne, Brisbane, Perth, Adelaide, and Rhodes, we are trusted by 2,000+ IT providers, government departments, and Fortune 500 companies. Our labs use PC-3000 tools, antistatic benches, and cleanroom environments for the highest success rates.

- ISO-certified Class-100 cleanrooms

- 90%+ success rate for hard drives

- Transparent, no-pressure pricing

- Over 2,000 verified 5-star reviews

- Specialists in hardware faults: head crashes, firmware, PCB

- All work done in-house by expert engineers

This hard drive PCB repair case study is just one example of how our team delivers results when others give up. If you’re facing a similar issue, let us help you recover what’s important.

Read more verified client reviews on our testimonial page.

Costs and Timeline for PCB Repair

We offer a free assessment with no obligation. Costs range from AUD 375 to 2,000 for most jobs. Hardware issues like PCB faults are more complex, but turnaround is usually 1–3 weeks. Faster options are available for emergencies.

Similar Devices We Handle

We repair circuit board damage on a wide range of drives, including:

- Western Digital My Passport, MyBook

- Seagate Barracuda, Expansion, Backup Plus

- Toshiba Canvio

- Samsung M3, P3 portable drives

- Hitachi Travelstar, Deskstar

Ready to Retrieve Your Files?

Don’t risk permanent data loss. Book a free assessment and let our engineers help.

- Book a free assessment

- Phone: 1300 444 800

- Read more testimonials

- Abroad? Post your device to us for expert recovery

Our Labs Across Australia

Real engineers, real labs — not drop-off points:

- Sydney: Level 11, 65 York Street

- Rhodes: Ground Floor, 5 Rider Boulevard

- Melbourne: Level 11, 456 Lonsdale Street

- Brisbane: Level 10, 95 North Quay

- Adelaide: Level 30, 91 King William Street

- Perth: Level 28, AMP Tower, 140 St Georges Terrace

Want to learn more? Read about Western Digital My Passport drives or view their latest portable hard drive lineup.